Unveiling the intricate dance of electrons within the realm of electrical circuits, where power flows effortlessly and timid whispers become roaring waves of energy, we delve into the mysterious world of contactors. Pulsating with precision and bridging the gap between control circuits and powerful machinery, these mighty switches wield the power to control the invisible forces that mold our electrified realities. Join us, as we embark on a captivating journey of discovery, unravelling the enigmatic pathways of a contactor’s wiring diagram, where logic meets artistry and electricity dances to the symphony of mechanical ingenuity. Embrace your inner engineer and prepare to be captivated by the neutrality of knowledge as we unveil the secrets behind this fantastical portal to the heart of electrical power.

Understanding the Basics of a Contactor Wiring Diagram

Exploring the Fundamental Components of a Contactor Wiring Diagram

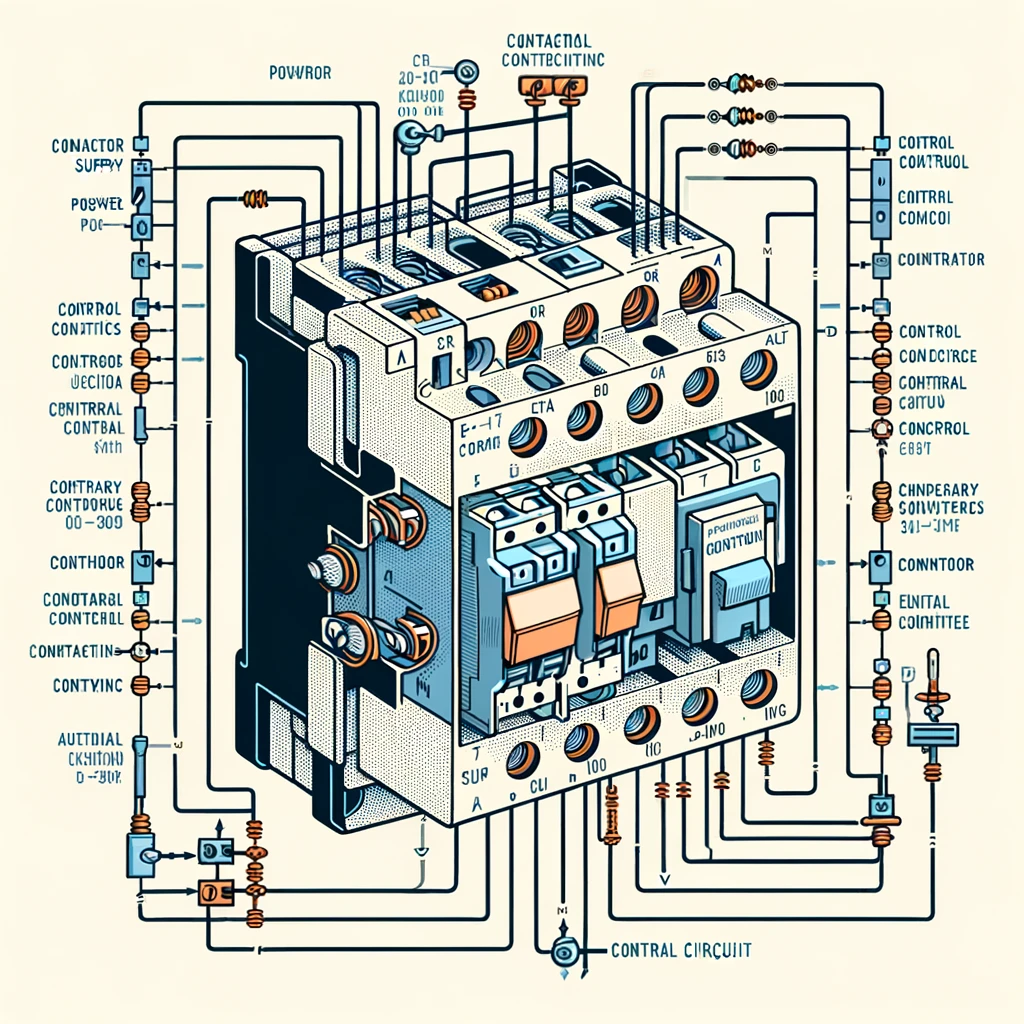

When delving into the world of electrical systems and wirings, it is essential to have a solid understanding of the basics involved. One such crucial element is the contactor wiring diagram. This diagram serves as a visual representation of how various components of a contactor interact, ensuring the smooth and efficient operation of electrical circuits.

Let’s unravel the intricate elements present in a contactor wiring diagram:

- Power Supply: The diagram typically begins by illustrating the power supply, which serves as the source of energy for the electrical system. This power can originate from a power grid, generator, or any other suitable source.

- Control Circuit: Branching out from the power supply, the diagram showcases the control circuit. This circuit includes switches, relays, and other control devices that regulate the flow of electricity, activating or deactivating the contactor as required.

- Contactors: Next in line are the contactors themselves, often depicted as boxes with input and output terminals. These magnetic devices play a crucial role in establishing and breaking electrical connections. Contactors are typically employed in applications where high voltage or current needs to be controlled.

- Coil and Contacts: Inside the contactor, we have the coil and contacts. The coil acts as an electromagnet, creating a magnetic field when energized by the control circuit. This magnetic field attracts the contacts, closing the circuit and allowing electrical current to flow.

- Overload Protection: To safeguard the electrical system from excessive current, the diagram may include overload protection devices such as thermal relays or overload relays. These ensure that the system doesn’t experience damage due to overload conditions.

- Auxiliary Contacts: Some contactors feature auxiliary contacts that perform additional functions beyond the main contacts. These auxiliary contacts can be used for signaling, control feedback, or interlocking with other devices.

is a stepping stone towards comprehending the intricate nature of electrical systems. By studying these diagrams, individuals can gain the knowledge needed to troubleshoot issues, design new systems, or simply expand their understanding of the fascinating world of electrical engineering.

Key Components and Connections in a Contactor Wiring Diagram

A contactor is an essential component in electrical systems, responsible for controlling the flow of electricity to different devices. To understand how a contactor functions, it is important to grasp the key components and connections within its wiring diagram. By examining these elements, a clearer picture of how electricity is regulated in a contactor can be revealed.

1. Main Power Supply: The main power supply provides the initial electrical energy to the contactor. It is connected to the contactor through the line terminals, which are typically labelled L1, L2, and L3.

2. Coil: The coil is a critical component that acts as an electromagnet, activating the contactor’s switching mechanism. It is connected to a voltage source, and when energized, generates a magnetic field that pulls the contactor’s contacts together or pushes them apart.

3. NO and NC Contacts: These terms refer to normally open (NO) and normally closed (NC) contacts found within the contactor. The NO contacts are designed to open when the coil is energized, allowing electricity to flow through the contactor. Conversely, the NC contacts are initially closed but open when the coil is energized.

4. Auxiliary Contacts: Auxiliary contacts are additional circuit-closing or circuit-opening contacts that can be connected to the contactor. These contacts are usually indicated by designations such as A1, A2, B1, B2, etc. They are often used for controlling other devices or signaling purposes.

5. Overload Relay: The overload relay acts as a protective device, monitoring the electrical current flowing through the contactor. If the current exceeds a predetermined level, the overload relay will trip and interrupt the circuit, protecting the contactor and other connected equipment from damage.

6. Control Circuit: The control circuit is responsible for sending signals to the coil of the contactor, allowing the control of its operation. It typically includes switches, push buttons, timers, or relays that control the contactor’s activation and deactivation.

7. Load Terminals: The load terminals connect the contactor to the electrical devices it controls, such as motors, lights, or heaters. These terminals are labeled T1, T2, T3, and sometimes T4, depending on the specific contactor model.

Understanding the provides invaluable knowledge for electricians and technicians working on electrical systems. It ensures the safe and efficient operation of various devices while retaining control over the flow of electricity.

Step-by-Step Guide to Creating an Effective Contactor Wiring Diagram

Understanding the Basics

Before diving into creating an effective contractor wiring diagram, it’s essential to understand the foundational concepts. Get familiar with the components involved and their functions:

- Contactors: Learn about the purpose and types of contactors used in electrical systems.

- Coil Voltage: Understand the significance of coil voltage and its role in controlling contactors.

- Control Circuits: Discover how control circuits are wired to activate or deactivate contactors.

Gathering the Necessary Tools

A reliable wiring diagram requires the use of a few tools to ensure accuracy and efficiency throughout the process. Take the following into consideration:

- Paper or Digital Platform: Decide whether you prefer sketching a diagram on paper or using digital software.

- Color-Coding System: Develop a color-coding system to make it easier to convey information and trace connections.

- Measuring Instruments: Utilize tools like a multimeter to verify voltage, resistance, and continuity for added precision.

Mapping Out the Circuit

When it comes to creating your wiring diagram, meticulous planning is key. Follow these steps to map out the circuit effectively:

- Identify Starting and End Points: Determine where the power supply initiates and where it should end in the circuit.

- Designate Contactors and Devices: Assign labels or symbols to represent various contactors and devices used in the circuit.

- Draw Connecting Lines: Connect the contactors and devices using clear, concise lines to establish their interrelationships.

Labeling and Finalizing

Now that the foundation is set, it’s time to add the finishing touches to your wiring diagram:

- Label Connections: Ensure that every line, connection, and component has a clear label for easy comprehension.

- Include Legends and Symbols: Create a legend or key at the corner of your diagram to define any special symbols or abbreviations used.

- Verify Connections: Double-check all your connections to guarantee accuracy and eliminate potential errors.

Best Practices and Troubleshooting Tips for Contactors’ Wiring

- Ensure proper wire sizing: It is crucial to select the correct gauge of wire for contactor wiring to avoid overheating or voltage drop issues. Consult the manufacturer’s guidelines or an electrician for appropriate wire sizing.

- Invest in high-quality contactors: Choosing reliable and reputable contactors can significantly reduce the likelihood of wiring problems. Opt for trusted brands that offer durable and well-designed products.

- Double-check connections: Before energizing the system, thoroughly inspect all wiring connections. Ensure they are tightly secured, properly stripped, and free from any signs of damage or wear.

- Label and organize wires: To simplify troubleshooting and future maintenance, label all wires and keep them well organized. This practice can save valuable time and minimize confusion during repairs or modifications.

- Maintain proper wire separation: Maintain adequate spacing between power and control wiring to prevent electromagnetic interference or “cross talk.” This separation helps maintain signal integrity and reduces the risk of accidental contact or short circuits.

- Implement safe wiring practices: Always follow safety guidelines when working with electrical equipment. Shut off power supply before making any wiring adjustments, use proper personal protective equipment, and adhere to local electrical codes and regulations.

- Test contactors regularly: Regularly test contactors by manually operating them and monitoring their performance. This practice helps identify any potential issues before they escalate, allowing for timely repairs or replacements.

- Install overload protection: To safeguard both the contactor and the connected equipment, consider installing overload protection devices such as fuses or circuit breakers. These protective measures prevent excessive current flow and can prevent catastrophic failures.

- Consult a professional when troubleshooting: If encountering complex or persistent wiring issues, it is recommended to seek expert help. Experienced electricians or contactor specialists can provide valuable insights and efficiently solve complex problems.

Q&A Wiring Diagram For a Contactor

Q: What is a wiring diagram for a contactor?

A wiring diagram for a contactor is a visual representation of the electrical connections and circuitry involved in the operation of a contactor, which is an electrical switch used for controlling an electrical power circuit.

Q: Why is a wiring diagram important for a contactor?

A wiring diagram is essential for a contactor as it provides a clear and concise illustration of how the various wires, terminals, and components should be connected. It helps electricians or individuals understand the wiring configuration and ensure proper installation and operation of the contactor.

Q: How does a wiring diagram for a contactor look like?

A wiring diagram for a contactor typically consists of lines representing electrical wires, labeled symbols for various components, and markings indicating the connection points or terminals. These diagrams are organized in a systematic manner to simplify understanding and troubleshooting.

Q: What are the key components shown in a wiring diagram for a contactor?

A wiring diagram for a contactor typically includes components such as the contactor coil, control circuit, power supply, overload relay, start and stop buttons, auxiliary contacts, and any other relevant electrical components required for proper functioning.

Q: How is a contactor wired using a wiring diagram?

To wire a contactor using a wiring diagram, one must first identify the terminals shown in the diagram. Then, the corresponding wires are connected to each terminal as indicated, ensuring proper wire routing and secure connections. Care should be taken to follow the diagram precisely to prevent any wiring errors.

Q: Are there any safety precautions to consider when wiring a contactor?

Yes, there are several safety precautions to consider when wiring a contactor. It is crucial to disconnect the power source before working on the contactor’s wiring to avoid electric shock. Additionally, ensuring the contactor is de-energized and using appropriate personal protective equipment (PPE) is highly recommended.

Q: Can a wiring diagram for a contactor be modified?

While a wiring diagram serves as a standardized guide for contactor installation, it can be modified to accommodate specific requirements or additional components. However, any modifications should be made with caution and expertise in electrical systems to guarantee safe and reliable operation.

Q: Can a contactor work without a wiring diagram?

It is possible for experienced electricians or individuals knowledgeable in electrical systems to wire a contactor without a specific wiring diagram. However, for those less familiar with contactor wiring, using a wiring diagram is highly recommended to minimize errors and ensure proper functionality.

Final Thoughts

As we bring this electrifying journey to a close, we hope the sparks of knowledge have ignited a fire within, illuminating the intricacies of wiring diagrams for a contactor. From unravelling the mysteries of its circuitry to deciphering the complexities of its connections, we have laid the foundation for a solid understanding.

Just as a conductor orchestrates the symphony of electric currents, a properly constructed wiring diagram ensures a harmonious flow of power in the realm of contactors. It is an invaluable roadmap, guiding both the seasoned electrician and the fledgling enthusiast through a labyrinth of circuits.

Remember, when crafting your own wiring diagram, attention to detail is paramount. Each line, each symbol, carries the weight of accuracy and precision. As you sketch the intricate dance of conductors, relays, and switches, envision the pulse of electricity, coursing through the diagram, driving destiny’s wheel.

Now armed with knowledge, venture forth with confidence, for the contactor shall no longer be an enigma but a partner in your electrical pursuits. Whether it is controlling motors, lighting up a room, or engineering technological marvels, your newfound proficiency in deciphering wiring diagrams will elevate you to new heights.

As we bid adieu, let us embrace the electrifying world of contactor wiring diagrams with open minds and zealous hearts. May this article serve as a guiding light, fostering a never-ending curiosity to unravel the mysteries that lie within the realms of electricity and its intricate circuitry.

For the contactor, no longer shall it be an elusive entity wrapped in confusion, but a trusted companion in the symphony of power. Now, go forth and let your skills in wiring diagram creation shine brighter than a thousand volts, ever illuminating the path towards electrical mastery.

A Boston University Electrical Engineering graduate.

Electronics designer for EV giants like Tesla, BMW, VW, and Ford.

Enthusiastic Wikipedia moderator in the automotive category and author of automotive articles.

Passionate about tech, travel, and cars.